Turning high chromium cast iron slurry pump tool – cubic boron nitride (CBN) tool

Slurry pump as everyone knows, bad work environment, higher requirements for product performance, the main parts of pump shell, the impeller as worn parts, high chromium cast iron is often used as the main material, but the high hardness of the high chromium cast iron, and belongs to the intermittent cutting impeller, the cutting tool abrasion resistance and impact toughness of the demand is higher. So in the rough car high chromium cast iron slurry pump parts to choose what tool is suitable? With the continuous research and development of the tool industry, CBN tools appear new material, can effectively solve the high chromium iron slurry pump difficult processing problem.

1. The main material of high chromium cast iron slurry pump

As a result of the slurry pump working conditions, often working in corrosive material such as strong acid, strong alkali environment, lead to short service life, the service life of the slurry pump in order to get high. High hardness and wear resistance, often use high strength and high hardness, strong corrosion resistance and abrasion resistance of high chromium alloy cast iron as the main material of slurry pump.

But the high chromium alloy cast iron is very difficult to process, not only the hardness is high, and the allowance is large, how to process?

2. High manganese steel slag slurry pump parts processing technology

There are many parts of the slurry pump, the main components are impeller, pump shaft, jacket, front guard plate, rear guard plate, pump shell, and shaft seal device. The following is a brief introduction of slurry pump parts impeller and pump shaft (as shown below) processing technology.

Impeller processing technology: coarse car inlet port ring and front plate surface — fine car front port ring and inner hole (to ensure concentricity requirements) — keyway (to ensure keyway symmetry) — drilling impeller balance hole (to ensure uniform size distribution) — inspection (balance test) — inspection storage.

Processing technology of pump shaft: rough car – heat treatment (tempering) – semi-finishing car – finishing – milling keyway – grinding – check storage.

3. How to select tool materials for processing slurry pump parts with large spare capacity and high hardness?

Slurry pump parts belong to the majority of casting parts, residual, and the size of slurry pump parts, such as the workpiece in order to ensure the completion of the workpiece will be appropriate in the casting process to increase the residual. For pump parts with large spare capacity and high hardness, it is necessary to pay attention to the performance and hardness of tool materials when selecting tool materials.

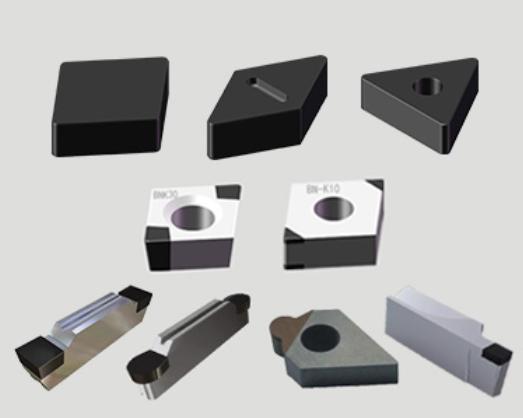

At present, there are three kinds of tools for processing slurry pump parts: the carbide tool, ceramic tool, and CBN tool. Personally, the CBN tool is more suitable for processing slurry pump parts.

From the hardness point of view: CBN tool > ceramic tool > carbide tool. From the toughness point of view: carbide tool > CBN tool > ceramic tool.

And developed a new CBN tool material – non – metal adhesive CBN tool bn-k1 material, in the processing of the slurry pump field has a good development.