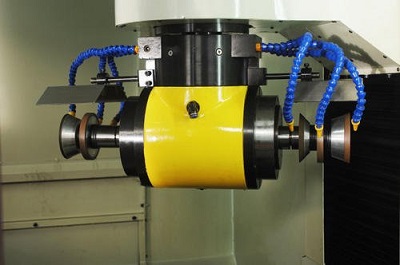

Abrasives for tool grinders are used as tools to cut the surface of workpieces and are collectively called grinders. Universal tool grinding machines, such as PP-50 Universal Tool Grinder, can process a variety of surfaces. Such as internal and external cylindrical and conical surfaces, planes, gear tooth surfaces, spiral surfaces, and various molding surfaces, etc.. It can also sharpen tools and cut the process range is very wide. Because grinding is easy to obtain high machining accuracy and good surface quality, grinding machines are mainly used for precision machining of parts, especially for hardened steel parts and special materials with high hardness. Now let’s introduce the structural design requirements of the universal tool grinder workbench.

The structural design of the PP-50 Universal Tool Grinder table usually meets the following requirements:

1. Tool grinding often requires roughing of all cutting surfaces in one clamping, and the workbench should capable of multi-chip grinding.

2. The tool is mainly composed of various complex curved surfaces. So the table structure should meet the requirements of multi-axis simultaneous processing to ensure that each motion axis does not produce motion interference within the working range.

3. The worktable must not only able to withstand the huge grinding force generated during rough grinding, but also to ensure high precision during finishing. Therefore, it is required that the machine tool has good rigidity, good stability, high motion accuracy, and small thermal degeneration.

Beijing Demina Precision Instrument Co., Ltd. has been committed to the production and research and development of various tool grinding machines. Each product has undergone strict quality management, and its quality has been affirmed by domestic and foreign customers. Users are welcome to come to buy.